Since this is implemented in the device itself, the response is immediate and does not rely on the PC software, increasing reliability and safety.Īt the same time, various user-interface controls can be connected to PoKeys devices – multiple MPGs (manual pulse generators), LCD, switches, indicators, etc.

PoKeys devices also constantly monitor limit switch states and stop the machine immediately if any of the configured switches trip. When used in conjunction with CNC software, PoKeys devices get detailed instructions from the software, running on the PC, and generate the required number of pulses in a specified direction for each motor. PoKeys as USB CNC controllerĪlthough PoKeys devices are general-purpose USB IO interfaces, PoKeys devices contain specialized support for the control of CNC machines. The result is the smooth and reliable operation of the machine.

The USB CNC controller is constantly loaded with required motion trajectory data in advance, so that it knows where to move despite the short communication outages. USB changes that by implementing so-called buffered motion.

Usb to parallel port cnc software#

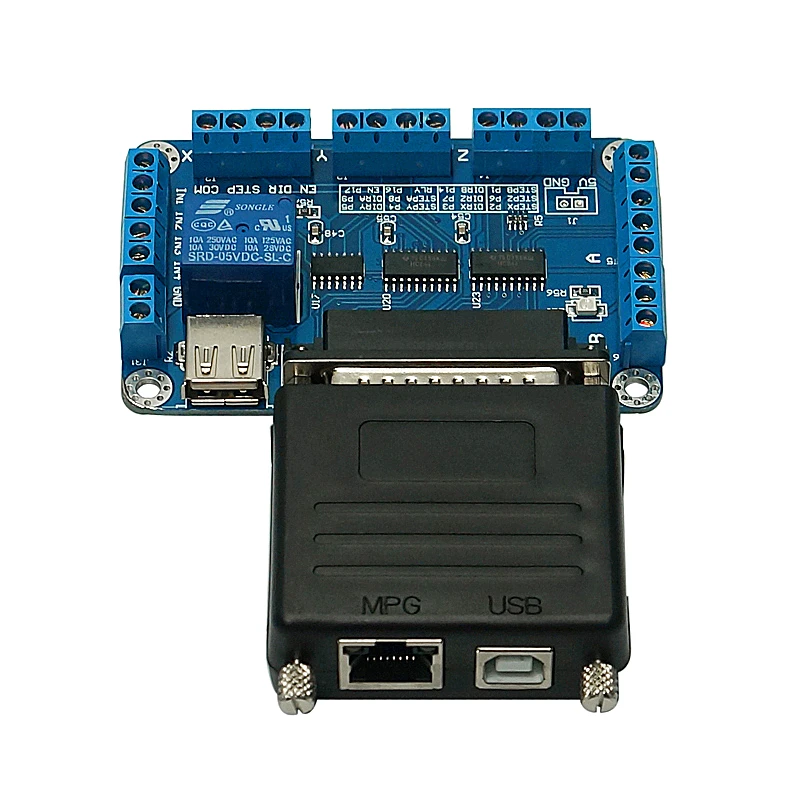

Moreover, in the times of LPT port usage, PC software was in charge of producing every single pulse for the motors, and failing in doing so for a short period (due to the operating system needing to focus on something else) caused the dreaded missed steps and machine lost the position, resulting in damage to the workpiece and/or machine. Right! But unlike LPT ports, where CNC motor control signals can be directly connected to, usage of USB requires the use of a USB CNC controller device, which can communicate with the computer over a standard USB bus on one end and exposes standard CNC machine-related signals on the other end.ĭue to increased communication overhead and non-realtime behavior of the USB bus, these USB CNC controllers must also take over all low-level machining operations, like homing, probing, etc. It is therefore logical that these ubiquitous high-tech high-speed buses can be utilized for the use with CNC machines, right? USB communication bus is a standard bus that all newer PCs are equipped with. In the 2010s, parallel ports are becoming extinct and simple solutions to interfacing a standard PC with a CNC machine are becoming rare. Parallel (LPT) port-based CNC motion controllers were highly popular in the past, driving a widespread of hobby CNC machines and a plethora of various affordable LPT motion controllers, which were also used in smaller and medium-sized commercial CNC machines. Smaller CNC machines often use a standard off-the-shelf PC and a customized interface to motor drivers. Now, let’s talk about USB CNC controllers more specifically… USB CNC controllers Let it be a mill, a lathe, EDM, or a plasma cutter, the precise positioning of the work tool is controlled and supervised by a CNC controller, which generates signals that turn or move the actuators (motors) of the machine. These machines drive the production of complex and precisely dimensioned objects out of a variety of materials. I'm sorry you're having so much trouble with this damn thing, my friend! It's about time it straightened up for you.Nowadays, one cannot imagine production processes without the use of computer numerical control (CNC) machines, controlled with USB CNC controllers, If the old power supply is working well, and you know what it's output and capacity is, (and that's within the requirements of your equipment) I don't see why you couldn't re-use that. With all the trouble you've had getting the original one to work (that's what I'm assuming this is), I think you'd be better off investing in a new controller that 's well documented, and works well with other CNC components. You could go to all the trouble of replacing it and have it blow up on the first try, also. I have seen people just snip off the "legs" from chips like SMD's, then solder right onto the stubs of the legs, instead of trying to unsolder/resolder, but again, what a PITA, and you'd be no closer to discovering why the first one blew up. The circuit board you pictured doesn't look like it's SM, but still, as Marty says, what a PITA. Good chance you can burn up adjacent components and PC board traces. Op amps are cheap and readily available, the "only" problem is that unless they're socketed, it's a giant PITA to unsolder them and put in a new one.

0 kommentar(er)

0 kommentar(er)